hpmc rdp siv hauv Cement Render & Plaster EIFS & ETICS

JINJI® HPMC muaj cov khoom sib txawv uas ua rau nws ua tau zoo thiab nyiam rau EIFS&ETICS.

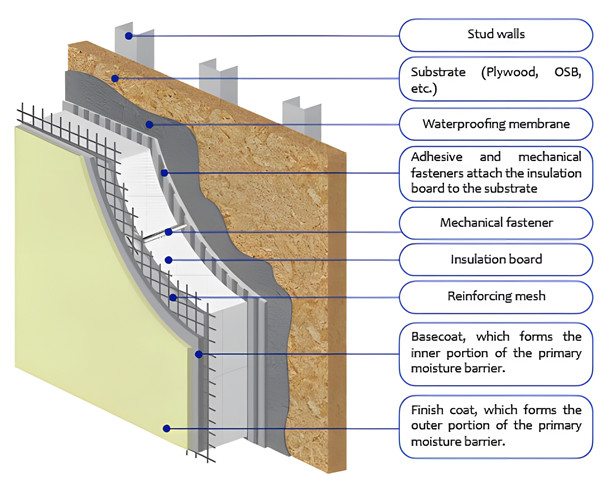

Thermal rwb thaiv tsev board system, feem ntau suav nrog ETICS (EIFS) (External Thermal Insulation Composite System / Sab nrauv Rwb thaiv tsev Finish System), thiaj li yuav txuag tau tus nqi ntawm cov cua sov los yog cua txias zog, ib tug zoo bonding mortar yuav tsum muaj: yooj yim rau mix, yooj yim rau kev khiav lag luam. , rab riam tsis nplaum; Zoo anti-hanging nyhuv; Zoo pib adhesion thiab lwm yam ntxwv. Lub plaster mortar yuav tsum muaj: yooj yim rau do, yooj yim rau kis, tsis-stick riam, ntev txoj kev loj hlob, muaj peev xwm ntub dej zoo rau cov ntaub net, tsis yooj yim los npog thiab lwm yam ntxwv. Cov kev cai saum toj no tuaj yeem ua tiav los ntawm kev ntxiv cov khoom tsim nyog cellulose ether xws li Hydroxypropyl Methyl Cellulose (HPMC) rau hauv mortar.

Peb cov khoom HPMC cellulose thiab cov khoom RDP muab cov kev txhim kho hauv qab no rau EIFS:

• Txhim kho cov nplaum nplaum thiab ua kom yooj yim: cellulose muaj cov thickening zoo thiab lubricity, uas tuaj yeem txhim kho cov nplaum lub zog thiab hloov tau ntawm EIFS nplaum.

• Txhim kho cov dej tuav thiab ncua sij hawm ua hauj lwm: txo cov dej tsis zoo rau hauv cov txheej txheem hauv cov txheej txheem. Cov dej tuav lub peev xwm ntawm cellulose kuj txhawb nqa lub zog adhesion ntawm EIFS adhesives. Qhov no yog vim cov binders muaj sij hawm txaus rau hydration thiab tib lub sij hawm tsis poob dej.

• Optimized khoom sib xws thiab rheology: cellulose yog ib qho tseem ceeb ntawm kev kho kom haum raws li nyob rau hauv mortars tshiab. Kev sib haum xeeb tsim nyog ua rau cov plaster tshiab tuaj yeem txuas tau zoo rau ntawm phab ntsa thiab ua kom cov chaw du thiab siv tau yooj yim yam tsis muaj kev xav ntawm qhov nplaum. Cov tshuaj aqueous ntawm MelaColl yog qhov tsis yog-Newtonian system, thiab cov khoom ntawm nws cov tshuaj hu ua thixotropy.

• Txhim kho hydrophobicity: Tom qab ntxiv cov cellulose, qhov hydrophobicity ntawm EIFS tau txhim kho, cov nyhuv waterproofing yog nce.

• Txhim kho kev ua haujlwm: Kev ua kom zoo dua qub thiab txo qhov nplaum ntawm cellulose tuaj yeem siv tau yooj yim rau EIFS cov nplaum, uas yooj yim rau kev khiav lag luam thiab kev tsim kho, thiab tuaj yeem txhim kho kev tsim kho kom zoo.

• Txhim kho cov txheej txheem kev ua tau zoo nrog lub zog zoo thaum ntxov: cellulose ua ke ntawm cov ntaub ntawv polymer thiab cov khoom siv tsis zoo. Lawv tuaj yeem ua kom lub zog thaum ntxov ntawm lub mortar thiab lwm yam khoom tseem ceeb uas xav tau rau EIFS thiab kev tsim kho tshiab.

• Cov dej tsis zoo, kev sib raug zoo nrog cov khoom siv dav dav: cellulose txo cov dej tsis zoo rau hauv cov substrates hauv formulations. Lub peev xwm tuav dej ntawm cellulose kuj tseem txhim kho lub zog adhesion ntawm EIFS adhesives. Qhov no yog vim cov binders muaj sij hawm txaus rau hydration thiab tib lub sij hawm tsis poob dej.

• Ua kom muaj zog, muaj zog adhesion, thiab alkali tsis kam: cellulose muaj kev tuav pov hwm zoo, thickening khoom, ruaj khov tshuaj muaj zog tiv thaiv alkali nres.